|

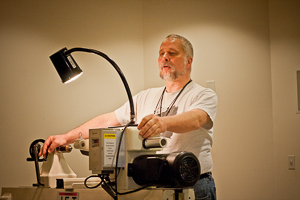

The main agenda item was Shop Safety, presented by George Chisholm (Woodcraft teacher). George gave a complete overview for safety in the shop in doing woodturning.

He covered such things as the disadvantage of bolting down a lathe to making sure you turn down the speed of the lathe when you finish. In other words, good habits

and much margin for error.

The main agenda item was Shop Safety, presented by George Chisholm (Woodcraft teacher). George gave a complete overview for safety in the shop in doing woodturning.

He covered such things as the disadvantage of bolting down a lathe to making sure you turn down the speed of the lathe when you finish. In other words, good habits

and much margin for error.

Revisiting the question of what one can safely wear while operating a lathe was a good set of reminders to anyone. One I had not heard yet: on the startup of grinders, which if cracked can come flying apart, so always stand to the side while starting.

The Presidents' Challenge was a piece with your best finish and/or the worst and indicate why. Harvey brought a piece with French polish (boiled shellac (Zinsser)

alcohol and equal part Linseed oil) which is good for small pieces that Harvey is so well known for.

Claude showed a salad bowl finished piece. John had a piece with 6 coats of wipe-on-poly. Mike showed a Tung oil piece that had 4K grit sanding followed by

the complete Beal wax process followed by a coat or Renaissance wax. George Lutz was up next to talk about his difficulties in replicating Bill Johnston's process.

Mike showed a Tigre Kaspy wood piece.

Claude showed a salad bowl finished piece. John had a piece with 6 coats of wipe-on-poly. Mike showed a Tung oil piece that had 4K grit sanding followed by

the complete Beal wax process followed by a coat or Renaissance wax. George Lutz was up next to talk about his difficulties in replicating Bill Johnston's process.

Mike showed a Tigre Kaspy wood piece.

Show-and-Tell: Claude showed a bowl that had a stone inlay ring in it. Mike showed a piece that had copper wire inlaid as horizontal rings.

He found that silver wire can turn out to be just silver coated copper wire, which after turning is just copper.

Tom showed a segmented piece with segments as staids, maple and walnut. Tom showed a segmented piece with segments as staids, maple and walnut.

Tom Haines showed a variety of platters and bowls with curved arcs of differing woods.

|