West Bay Woodturners Newsletter is a monthly update on the club activities. This free resource is available to beginner and professional woodturners.

Next Meeting

Wednesday, February 19,

7 pm at Bridges Church,

625 Magdalena Ave,

Los Altos, CA 94024

Program

February: Turning a whistle with a skew demonstration by Jon Bishop.

President’s challenge:

February: Take your pick:

- Natural (Live) Edge Bowl

- Winged Bowl

Upcoming Meetings and Demos

- March: TBD

- April: TBD

President’s Message

I hope everyone enjoyed our January meeting and I am glad everything went smoothly for my first as president. I especially appreciate how everyone is so happy to share the work they have done on the lathe. I always find I learn a few new things at every meeting.

At the next meeting I will demo how to make a whistle using the skew only. Well actually a lathe, a skew, a chuck, and a few other things. For me, this was a nice way to begin learning skew techniques, which have evaded me for quite a few years. I am guessing many others have attempted to go down that path and been scared away, so hopefully I will be able to dispel some of those concerns. It is actually quite a nice tool to use despite some of its difficulties. BTW, if there are any other skew aficionados who would like to say a few words during the demo please feel welcome – I am far from experienced on the skew myself and could use the help!

Looking forward to our March meeting, we still need to have someone give a talk or demo. I am thinking of something like off center bowl turning might be interesting. Any volunteers? Remember, just because you are giving a demo does not mean you need to be an expert at what you are demonstrating, so consider presenting whatever you have found interesting recently.

Jon Bishop

Website Update

The West Bay Woodturners website has just received a major update: We introduced a members-only area where you can find a list of WBW members with their contact information and photos. We care about security and privacy; we share only the bare minimum details with club members. That information is restricted to authenticated club members only.

The Membership area is not fully complete yet; the WBW officers are currently collaborating to fill in the up-to-date details.

You will need to set up your own login/password to authenticate to the WBW website to access our restricted content. When you do that, please choose a very strong password. No need to act now, we will follow up on that in a few of weeks when everything is thoroughly tested.

Sorry for reminding, please never re-use the same password; always use a unique password for each website. That is important because if one website is hacked for any technical or non-technical reason, your account will be hacked on other websites almost automatically if you re-use your password. Please keep your passwords strong and unique for each website, and maybe even change them regularly just to be sure.

Overall, if you forget someone’s name, check our new “Membership” area of the WBW website. And keep wearing your name tag so everyone remembers your name. Thanks!

Last Meeting Review

Wednesday January 15, 2025

Woodturners newsletter notes by Laura Rhodes, pictures by Angela Gunn and Roman Chernikov

Announcements

- Jim Koren, Treasurer

- 42-44 people have paid their 2025 dues. 10-15 people still need to pay

- Dues bring in $1500 to $1800 per year

- If you haven’t paid WBW membership dues yet, please bring a check (preferred) or cash to our meeting or pay WBW Dues online. Dues are currently $35/calendar year ($40 in March 2025).

- We invite you to contribute to our website by writing an article on a topic of interest to you. Roman Chernikov, our website coordinator, can assist you with publishing and help in many ways. If you have an idea for an article or have pictures of your projects in progress, please don’t hesitate to reach out to Roman. He will guide you through the steps to get your piece published on our WBW website.

- Board of Directors meetings is on Tuesday, Jan 28th at 7PM via Zoom. Meeting is open to all.

- Dean Caudle, program director, said that Mark Gardner will be demonstrating in September.

- Jim Koren spoke about potentially pooling a large sandpaper order and using dies to cut circular pieces. If interested, email Jim.

- Jerry Galli gave several updates:

- The Oregon Woodturning Symposium is March 14-16 in Albany, OR. He indicated that the vendor area should be more comprehensive than that of last year’s AAW symposium because the venue doesn’t have a union issue related to unloading vendor equipment. Jerry has pen blanks and kits available for turning Pens for the Troops. Contact him if you are interested. He gave last year’s pens to Eric McCrystal at Woodcraft for distribution to the national organizers. Those who participated should be receiving a thank you email from Eric. Jerry contacted several West Coast based turners for potential club demonstrations, including: Scott Hampton, Mike Jakofsky (only if guaranteed 3-4 days), Craig Timmerman, and Todd Raines (Zoom only). Let Jerry know if you have suggestions.

- Roman wrote an article about a recent saw dust session about sanding bowls. Read it here: A Day at Woodturning Shop in Santa Cruz Mountains.

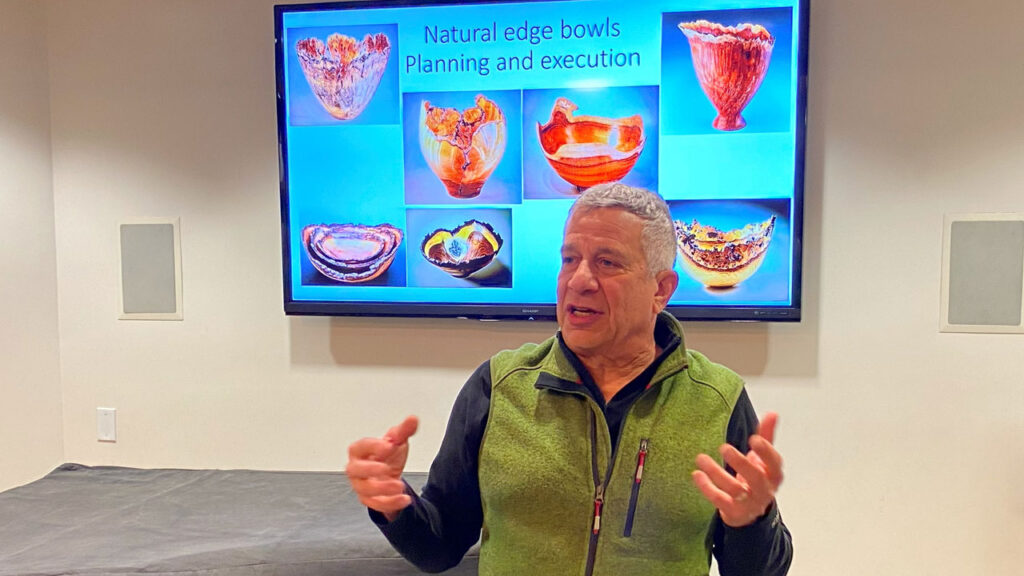

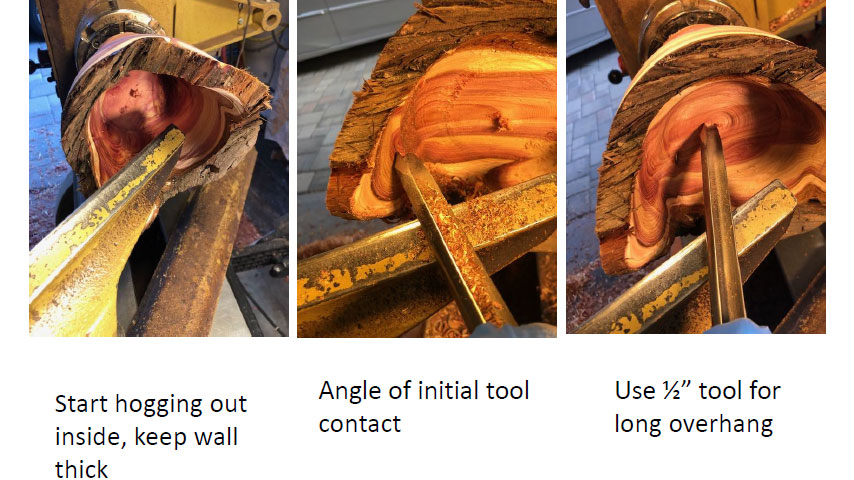

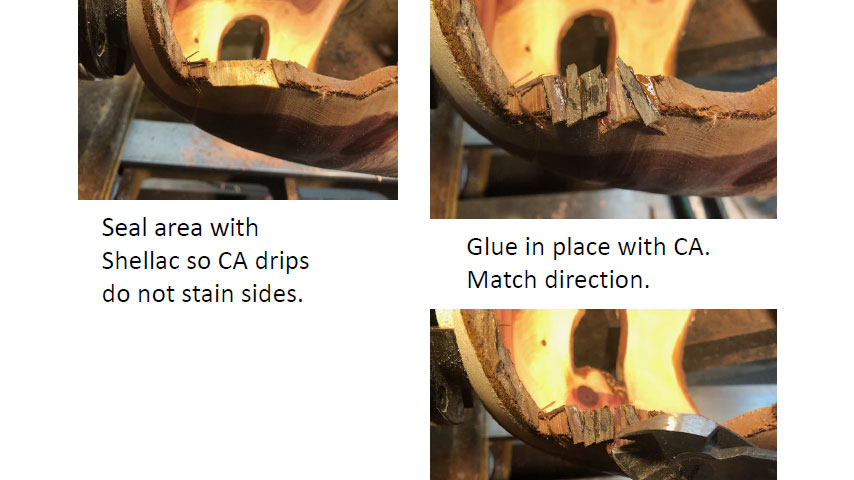

Presentation on natural edge bowl turning by Bob Bley

Bob Bley gave a comprehensive presentation on the turning of natural edge bowls, using his “Juniper Series” as examples. He noted that there are many variations with different woods with respect to the bark and to the resulting shape of the bowl. Cork oak sometimes has bark two to three inches thick. Bark sometimes stays on, sometimes, not. The outside shape of a log can vary quite a bit – round vs. convoluted. His example Juniper log’s cross sections varied significantly along its length.

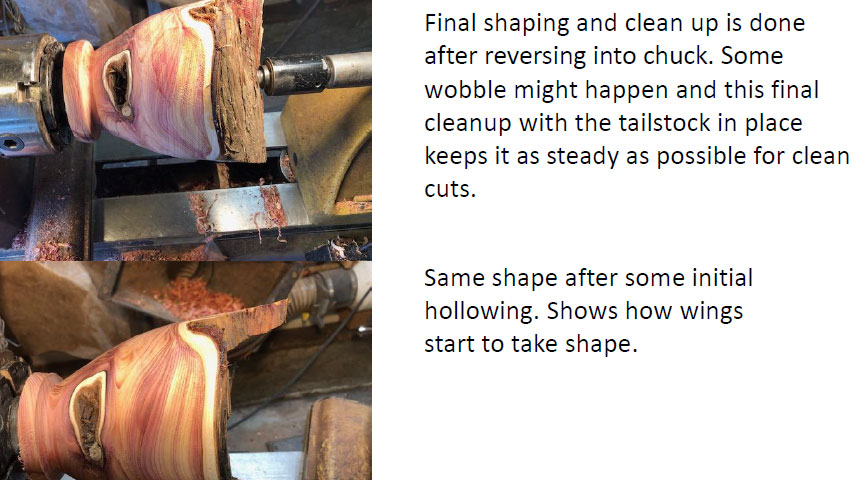

Bob typically once-turns his natural edge bowl using green wood. To mount the blank on the lathe between centers, he drills a flat-bottomed hole with a Forstner bit through the bark, into the sap and heartwood for the spur drive. He tries to find two balanced top edge high spots when turned round, adjusting the tail stock live center position to balance the piece. He also tries to position it such that the bark thickness on the top will be even.

After turning the piece round and adjusting the orientation to achieve the desired balance, Bob creates a tenon, making sure to have a flat spot on the bowl bottom for the chuck jaws to rest on. This will help ensure a strong, stable chuck holding. He does the final shaping of the bowl’s outside after he has flipped the blank around with tenon in the chuck with tail stock support. This ensures concentricity between the inside and outside.

Bob does an initial hollowing leaving all the walls very thick. Then, if leaving the piece on the lathe overnight, he wraps the blank in a plastic bag. He works down to the final wall thickness of about a quarter inch in stages, starting at the top of the bowl. He hogs out material from the bowl interior with a gouge. As he gets deeper into the bowl, he often switches to a longer tool rest and an EasyWood Finisher tool. Finally, he cleans up with a negative rake scraper.

Bob explained how sections of the rim where the bark has come off can be repaired. After shaping, seal the piece with shellac and then use thin CA glue to reaffix the bark, matching the bark “grain” direction. This will prevent CA glue from staining the bark. Trim the edges of the bark with wire cutters and sand smooth.

Bob sands after the piece has been drying in the house for several days. He spot sands on the lathe with the lathe stationery using a 2” padded sander with 3” sanding pad. To shape the bottom and get rid of the tenon, Bob uses a wooden jam chuck. He dresses the end of the jam chuck each time. Using the initial live center hole to recenter, he reshapes the bottom and decides where the bottom is. With the lathe off, Bob sands with rotary sander. He finishes with Tried & True original, two coats.

Presidents Challenge: Gift I made for the Holidays.

Jim Koren made a carved Mancala board of Alaskan Cedar (great aroma to carve) and made his first ever oak box for his grandson to hold rocks.

Claude Godcharles received a bell from Harvey Klein. The handle was cocobolo. Harvey explained that he first turned the bell and then drilled a hole all the way through. He made the handle with a tenon to fit that hole and with the tiny bit left of the handle stock, he turned the clapper. He used two eyelet screws to connect the clapper to the tenon of the handle so the bell actually makes noise.

Angela Gunn received a camphor bowl from Chip Krauskopf. Chip filled a hole with brass, put a bead on the top, and used his new laser tool to engrave his logo on the bottom.

Dan Boehmke made a black acacia bowl and gave it to Bob Bley.

Jon Sauer received a madrone bowl from Jim Koren. The bowl’s interior was painted using Eric Loftstrom’s technique and the bowl has significantly gone oval since turned.

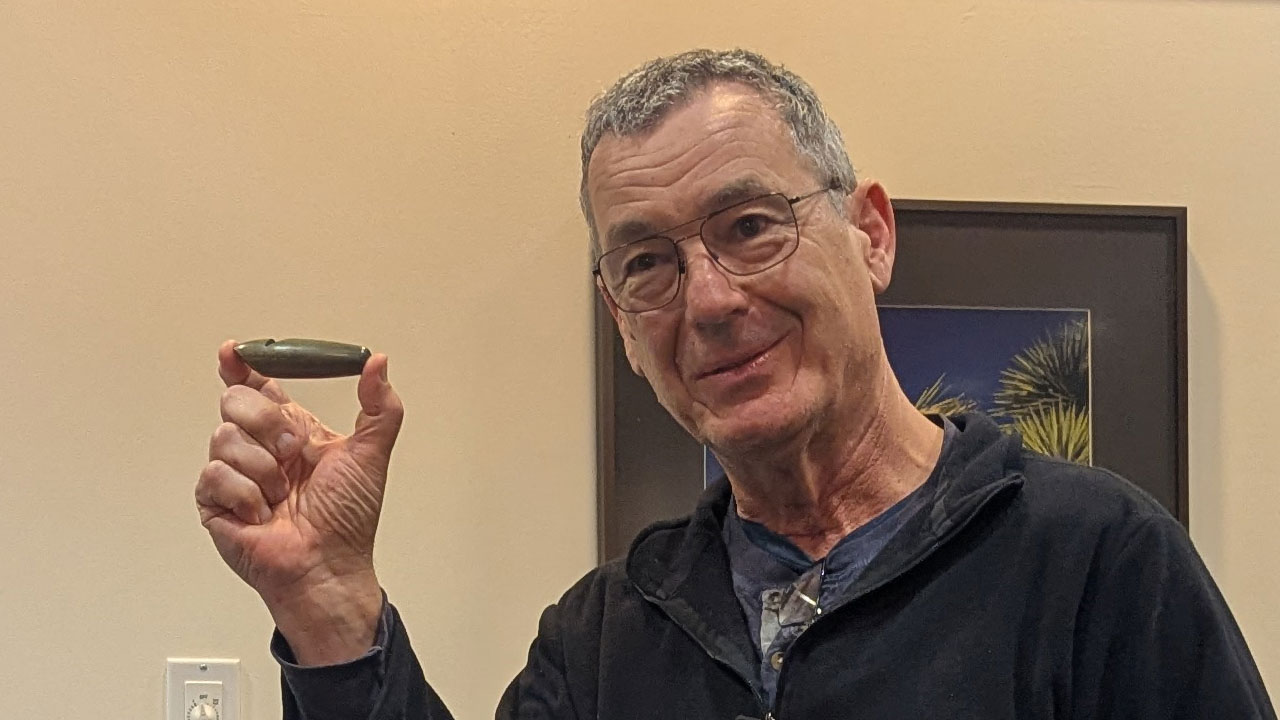

Jon Bishop gave a lignum vitae whistle to Chip Krauskopf. Chip gave the whistle a blow so all could appreciate its sound. Jon said the most difficult part of making the whistle was getting the dowel insert shaved and inserted properly.

Kelly Smith showed the bowl he received from Tom Mandle with an undercut rim and inserts. Kelly also showed a Christmas tree from black oak, a small holiday juniper bowl, and a ball of some mystery wood.

Jim Koren received a segmented vase from Gordon Peterson at the party (right side of the picture). The vase was made from walnut and redheart with gaspeite green stone. The piece was finished with about 20 coats of Emtech 6000 water-based lacquer. Gordon uses a rotisserie motor connected via a belt to his lathe handwheel to slowly turn the segmented piece as each coat of the lacquer dries.

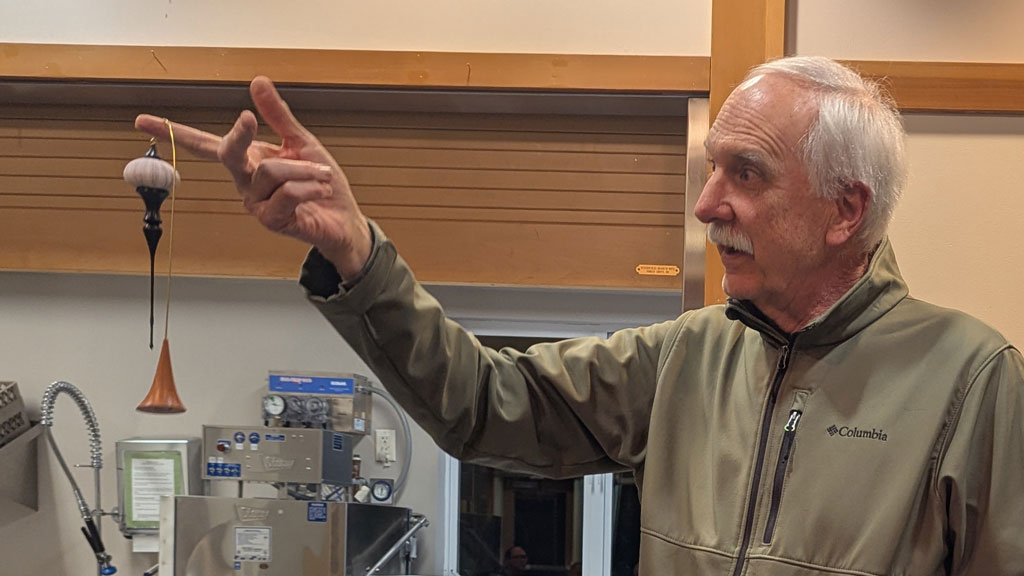

Dan Boehmke received a top from Jon Sauer. The top is made from a betelnut with a stand of blackwood turned on the Rose engine. A tagua nut forms an embellishment.

Show & Tell:

Dean Caudle turned a black walnut bowl. He also showed a commissioned black walnut urn with a brass insert.

Jerry Galli brought some live edge bowls, one of Chinese Pistache, the other from black acacia. Their bottoms are not yet finished. He sands the bowls to 600 grit and puts on a coat of General Finishes Bowl Finish. He then sands again to cut back the sheen. Jerry also showed a 13” Sycamore bowl finished with Drs. Walnut oil. The wood came from the log yard on Veteran’s Boulevard.

Al Holstein brought a sycamore bowl. He burned a decorative rim using a magnifying glass holding the piece in the sunlight while shielding the areas not to be burned with a tin can.

Tom Gaston brought in a walnut bowl with mahogany and maple inlaid stripes in the bottom. He cut the kerfs with the table saw and filled them with the wood strips before turning. He showed a pecan bowl that went radically oval. Tom also showed a couple of other bowls, one of oak, the other of unknown wood.

David Vannier showed egg shaped boxes with intricate carvings. He also brought two urns he turned for the recently passed woodcarving carving club president, Alan Huntzinger, and for future use for his wife. The urns were turned from wood from a birch tree from Alan’s backyard. The wood was past its prime and Dave had to patch a large hole. Alan’s wife’s urn had a shell on the top because she makes jewelry. In a collaborative effort, Roman Chernikov is creating a carving for the top of Alan’s urn.

Dale Bassman showed the holiday ornaments he made for his family using knife scale blanks made from multiple layers of colored wood. The ornaments were carved on his Rose engine and the carvings exposed different colors of wood.

Joe Martinka turned some spindle samples showing the difference between using the scraper and the skew chisel (as Eric Lofstrom showed us in his demo). Joe also turned some egg shapes and even made a captive ring with the skew. Joe also brought a Stewart Batty style wooden handle. Joe also brought a black acacia bowl. He found the wood difficult to turn using conventional tools, but the carbide tools worked better.

Mark Koenig acquired a bunch of sea urchin shells back in 2018. He finally used them to create ornaments. To stabilize the shells, Mark using spray foam insulation. His ornament had a very long, elegant finial of ebony and was held in an Ashley Harwood style stand – a turned cone, trimmed at an angle. Using a larger 4” sea urchin shell, Mark created a Sally Ault style rosewood box.

Jim Koren made a mini box with wood he took home from Dennis Lillis’. This was the second box he’s made.

Angela Gunn’s goal this year is to become comfortable with turning bowls. She received a poplar blank from Tina. She really likes the shape of the resulting bowl but is less thrilled with the look of the wood itself.

James Craig made a “twice-poured” bowl from pithy eucalyptus. He had turned through the bottom and so filled the bowl with resin, creating a glass-bottomed bowl.

Dan Boehmke has been experimenting with different finishes. He brought several bowls of walnut and black acacia. One was finished with Tried & True Danish Oil. The next with three coats of General Finishes Bowl Finish. The finish he liked best was putting on a heavy coat of General Finishes and then sanding to 600 grit and finally adding 2 thin coats of General Finishes Bowl Finish.

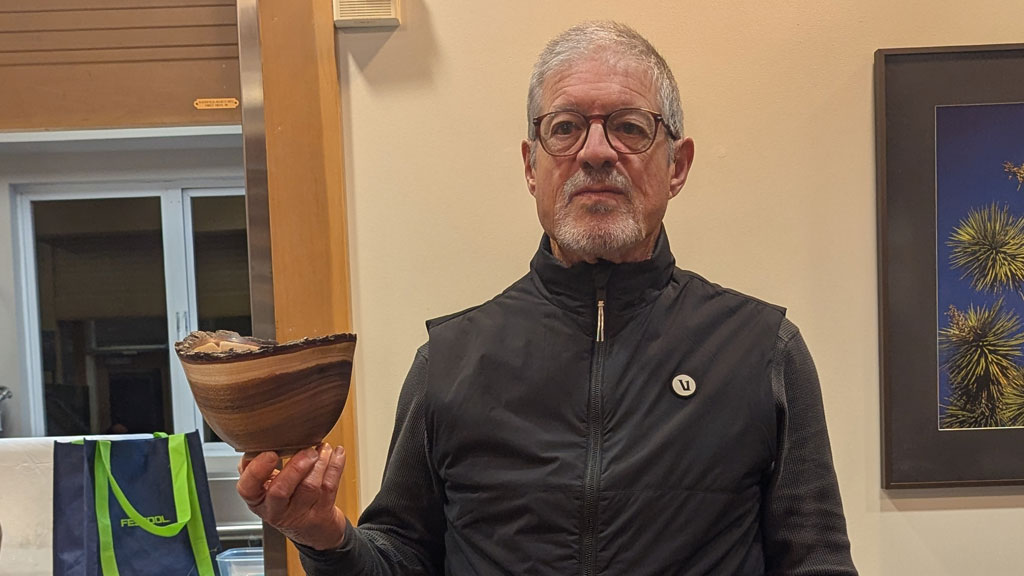

Bob Bley brought several of his juniper live edge bowls. He compared the difference between the shiny finish achieved with wipe-on poly and buffing versus the more matte Tried and True finish.

Claude Godcharles turned an enormous natural edge buckeye burl bowl. He embellished it with a bead on the bowl’s exterior and ripples along the bowl’s interior bottom. At this point, there is no finish on the bowl and Claude was soliciting advice from the club members on what to use. Someone suggested a General Finishes water-based polyurethane.

Jon Sauer brought in some pieces from other turners from his personal collection. One was an$8 thrift store find – a vase turned from mamaku (a.k.a. Black tree fern) from New Zealand. Some speculated that the wood may have been stabilized. He also brought an ant sculpture made by Michael Sage that is reminiscent of the old children’s game, Cootie. The sculpture has articulated legs and the head of the ant also forms a miniature box.

Participation Prizes

“As the Wood Turns” by David Vannier

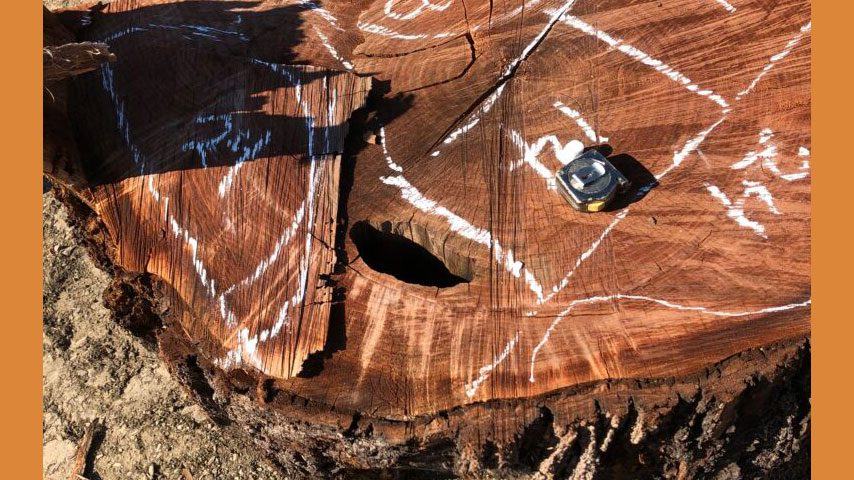

Thanks to Brad Bond, we had an awesome wood event. Brad arranged for us to go into the hills, just over an hours drive for me, to process some walnut.

The pictures that he sent out before didn’t prepare me for what was ahead. A little maneuvering was required to stay out of the owners way as they were running a wood mill. But they set aside plenty of room for us to work. After arriving, they showed us the pieces that were too small for them. They then moved the pieces with a forklift to our cutting area. Before starting, we had a little safety talk. Yes, the thought of having up to 8 chainsaws running at one time had me nervous. But, all in all, people worked safely, and my fears were not needed. I spent a good part of the time marking blocks to be cut.

Mostly we were all in agreement on shooting for 14 or 15” bowl blanks. Fred was a bit more ambitious, looking for a 22” or bigger blank. Yes, the wood was big enough to support that. I look forward to seeing his version of the “baby bath tub”, my term for bowls that big. Yes, I have one. I made it to someone’s specs, but when they saw it, they said “who would want anything that big?” Yes, I still have it. But last year at one of the shows I do, someone asked if I had anything larger. No, I’m not interested in doing that again! One thing about the wood that size is it was from a very old big, heavy tree.

Almost all of the wood that we got was highly figured. A few pieces of burl were there, and i don’t remember who the lucky turners were that collected it. I’d like to thank all the young people that helped/loaded my van with the 5 pieces i gathered. By the end of the day, I was too tired to load it. Unloading was easy, just slide it out to the hydraulic lift table, and away it goes. I then we spent the following day with 6 hrs of bandsaw and chainsaw work. My bowls are all roughed, and sealed. Now to wait for it to dry so i can finish turning it. One is a calabash like bowl, which i don’t think will be going anywhere. Someone asked me if i had done events like this before. Yes, in the 25 years I’ve been turning, we’ve had quite a few. Some have been busts, but no way this one could be described as anything other than awesome!

Woodturners Newsletter Editing Notes

WBW members, please let the newsletter editors know if you have a personal website and would like it included in the President’s Challenge and Show & Tell sections of our Woodturning Newsletter. Email us at info@westbaywoodturners.com.

WBW board members and committee chairs

President: Jon Bishop

Vice President: Tom Gaston

Treasurer: Jim Koren

Secretary: Laura Rhodes

Member at Large: Dean Caudle

Meeting Program Coordinator: Claude G acting

Visiting artist Coordinator: Dean Caudle acting

Anchor seal: Dennis Lillis

Craft Supply: Tina

Librarian: Kelly Smith

Audio Visual: Curtis Vose, Edgar Whipple

Website: Roman Chernikov

Woodturners Newsletter: Angela, Jon, David, Laura, and Roman

Leave a Reply

You must be logged in to post a comment.